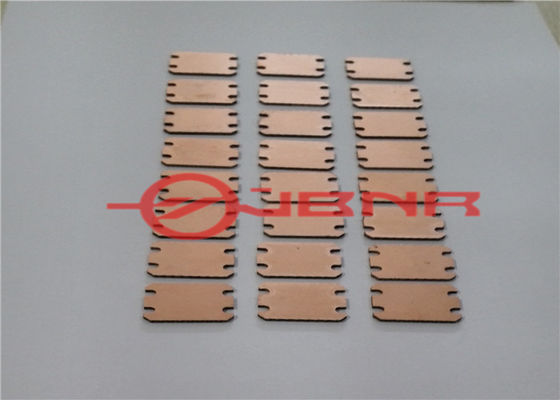

Excellent CTE And High TC No Voids of CMC Heat Spreader For Hermetic Packages

Description:

Cu/Mo/Cu(CMC) heat sink, also known as CMC alloy, is a sandwich structured and flat-panel composite material. It uses pure molybdenum as the core material, and is covered with pure copper or dispersion strengthened copper on both sides. Besides, copper molybdenum copper heat sink has adjustable coefficient of thermal expansion, high thermal conductivity, and high thermal stability.

S-CMC is a multi-layered Copper and Molybdenum clad metal, which has an excellent property both low CTE and high thermal conductivity. Its higher thermal conductivity compared to other same kind of materials contributes to highly powered electronic packages.

Product Properties:

| Grade |

Density g/cm3 |

Coefficient of thermal

Expansion ×10-6 (20℃)

|

Thermal conductivity W/(M·K) |

| CMC111 |

9.32 |

8.8 |

305(XY)/250(Z) |

| CMC121 |

9.54 |

7.8 |

260(XY)/210(Z) |

| CMC131 |

9.66 |

6.8 |

244(XY)/190(Z) |

| CMC141 |

9.75 |

6 |

220(XY)/180(Z) |

| CMC13/74/13 |

9.88 |

5.6 |

200(XY)/170(Z) |

Application:

Cu/Mo/Cu(CMC) heat sink has similar applications with tungsten copper heat sinks. It can be used as thermal mounting plates, chip carriers for microwave, flanges and frames for RF, laser diode packages, LED packages, BGA packages and GaAs device mounts etc.

S-CMC heat sink can be used in wireless communication packaging, opto electronics packaging etc.

Related Products:

We also offer tungsten copper heat sink (WCu), molybdenum copper (MoCu), copper molybdenum copper (Cu/Mo/Cu), copper molybdenum copper copper (Cu/MoCu/Cu) sheets or fabricated parts for microelectronics packaging and power devices.