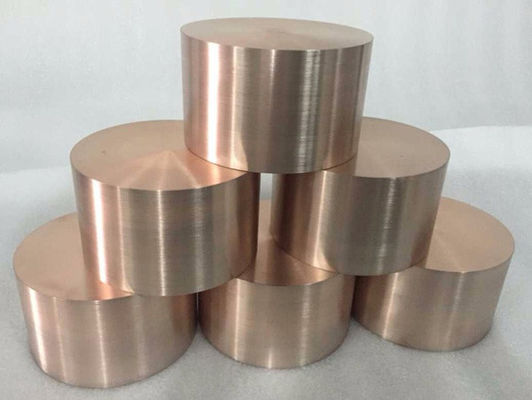

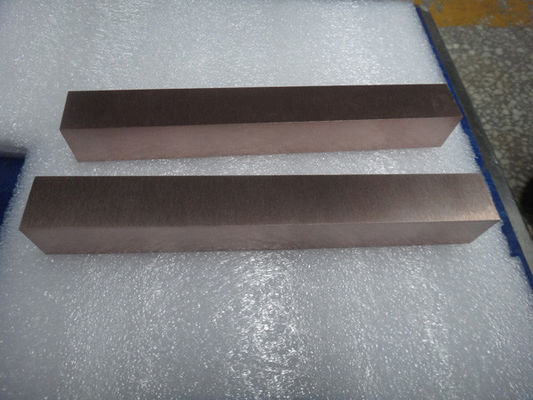

WCu80 Ring / Rod / Sheet / Bar Copper Tungsten Alloy For Electrical Discharge Machining

Detailed Product Description

| Material: |

Tungsten Copper |

Density: |

15.2 |

| Hardness: |

98HRB |

RWMA Class: |

12 |

| Application: |

EDM |

Electric Conductivity: |

34% IACS |

| Highlight: |

copper tungsten electrodes, copper tungsten |

WCu80 Ring / Rod / Sheet / Bar Tungsten Copper EDM Electrode

Description:

tungsten composites are used worldwide for EDM (Electrical Discharge Machining) and ECM (Electrochemical Machining) electrodes. All material is manufactured by the press, sinter, and infiltrate process. Virgin powders are used, resulting in a consistent homogeneous material giving high and even burning rates. Copper tungsten is used in plunger/sinker applications where intricate definition is required, especially in tungsten carbide.

Product Properties:

|

Class

|

Chemical Composition(Wt%)

|

Density

|

Hardness

|

Resistance rate

|

IACS

|

Bending strength

|

|

Cu

|

Total Additives≤

|

W

|

g/cm3≥

|

kgf/mm4≥

|

um.cm≤

|

%≥

|

MPa≥

|

|

W93Cu07

|

7±1.0

|

0.5

|

balance

|

17.5

|

270

|

7.2

|

26

|

1190

|

|

W90Cu10

|

10±2.0

|

0.5

|

balance

|

16.75

|

260

|

6.5

|

27

|

1160

|

|

W85Cu15

|

15±2.0

|

0.5

|

balance

|

15.90

|

240

|

5.7

|

30

|

1080

|

|

W80Cu20

|

20±2.0

|

0.5

|

balance

|

15.15

|

220

|

5.0

|

34

|

980

|

|

W75Cu25

|

25±2.0

|

0.5

|

balance

|

14.50

|

195

|

4.5

|

38

|

885

|

|

W70Cu30

|

30±2.0

|

0.5

|

balance

|

13.80

|

175

|

4.1

|

42

|

790

|

|

W65Cu45

|

0.545±2.0

|

0.5

|

balance

|

13.30

|

155

|

3.9

|

44

|

650

|

|

W60Cu40

|

40±2.0

|

0.5

|

balance

|

12.75

|

140

|

3.7

|

47

|

600

|

|

W55Cu45

|

45±2.0

|

0.5

|

balance

|

12.30

|

125

|

3.5

|

49

|

565

|

|

W50Cu50

|

50±2.0

|

0.5

|

balance

|

11.85

|

115

|

3.2

|

54

|

534

|

|

Application:

Arcing contacts and vacuum contacts in high and medium voltage breakers or vacuum interruptors

Electrodes in electric spark erosion cutting machines

Heat sinks as passive cooling elements of electronic devices

Electrodes for resistance welding

Electronic Packaging Materials

Product picture: